Breakthrough Fire Prevention Solution

Detectium's digital twin for risk & anomaly detection, leverages vision-based sensors, 3D model, cloud, and machine learning for fire prevention and rapid detection.

Key features include fire localization, intensity detection, real-time incident feeds for fire brigades/rescue teams, and real-time fire propagation simulation.

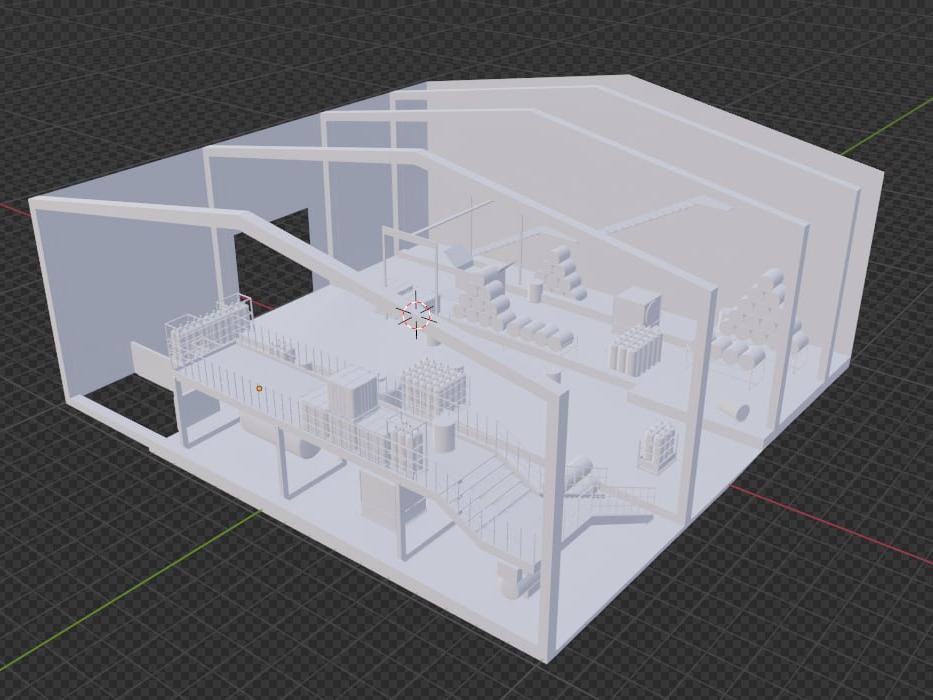

Digital Twin

Real-time visualization of fires combined with simulation for preventing fire damage to take fire safety to the next level

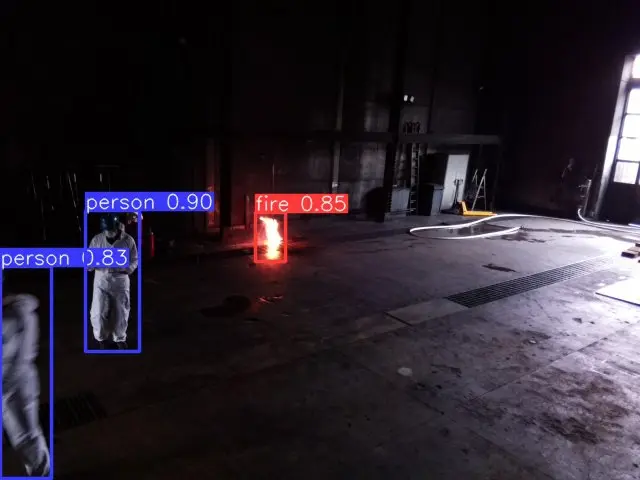

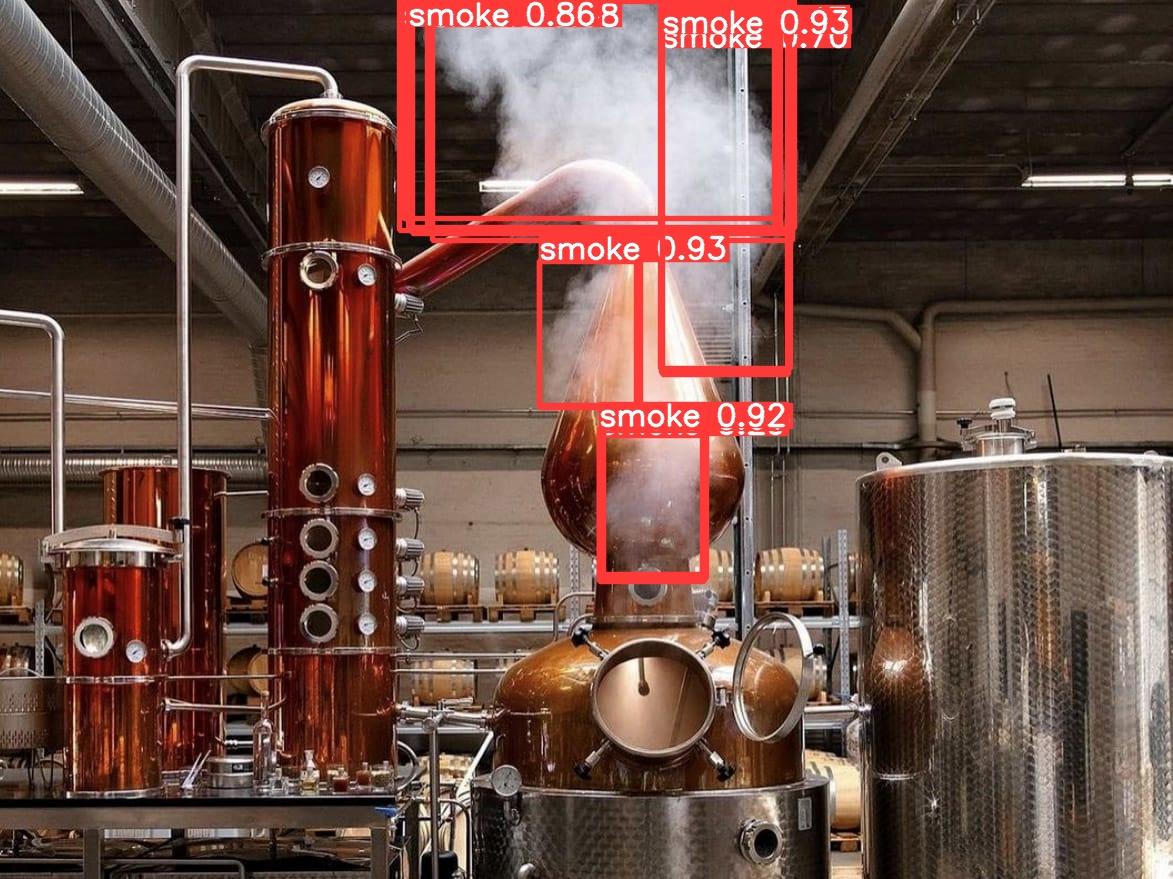

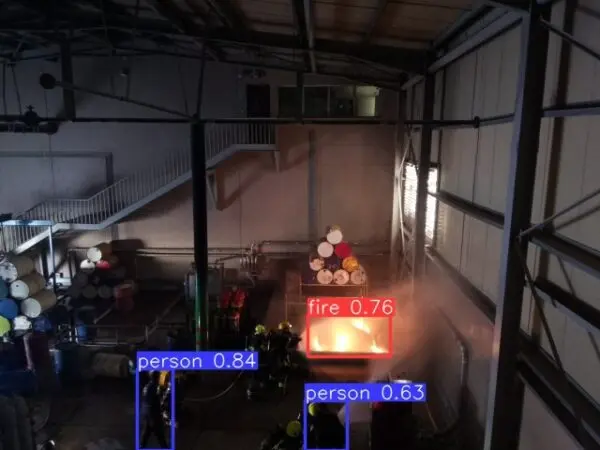

AI Model

Computer vision for more accurate detection and larger coverage compared to conventional solutions

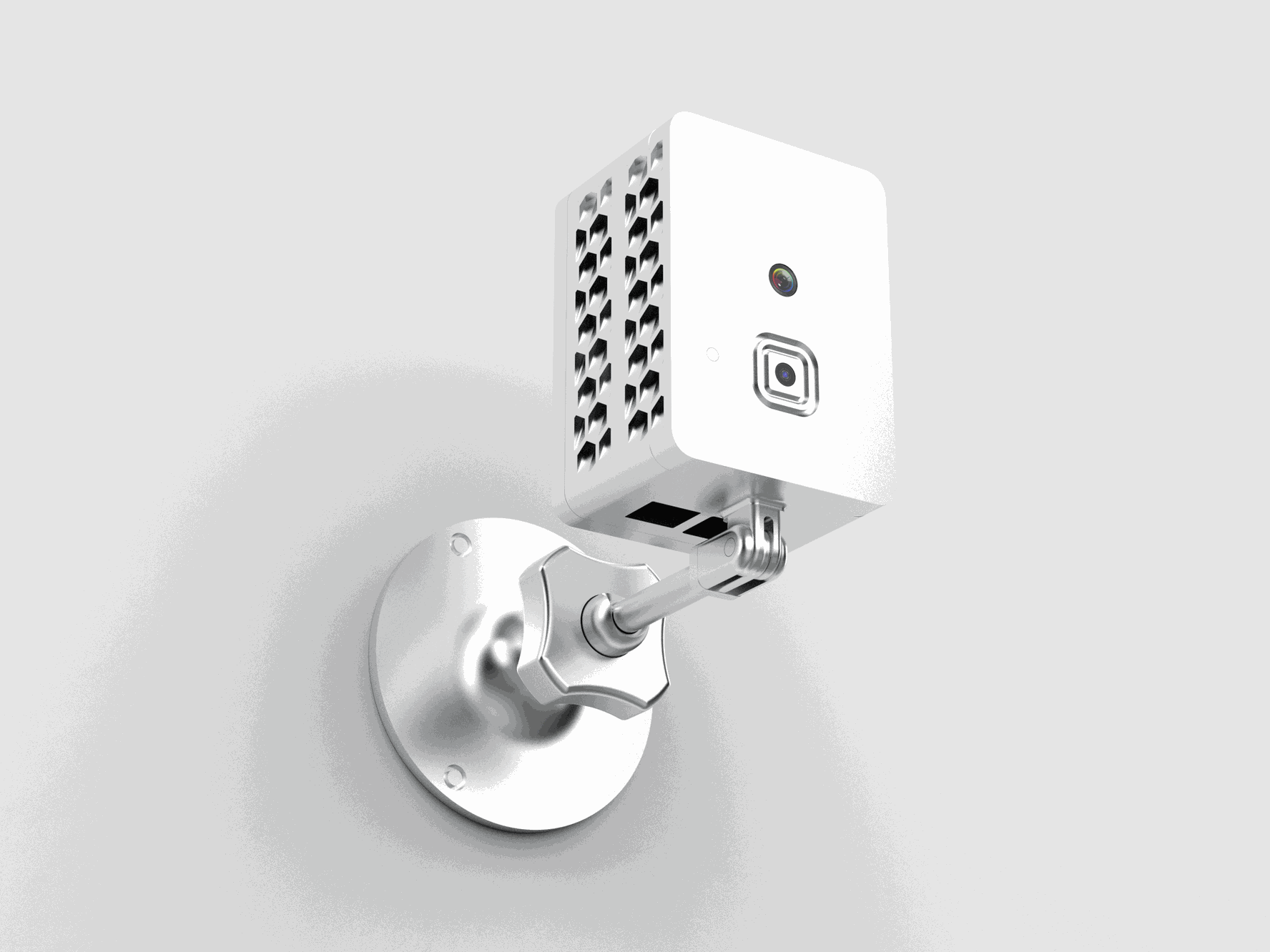

Sensor Package

Speed & Accuracy

Measured 80% faster detection and significantly reduced false alarms

Conventional fire detectors have limited coverage and are prone to false detections due to legacy technologies.

Detectium enables faster fire and anomaly detection without compromising accuracy.

Cost efficiency

Cover distances of more than 60 meters with

minimal hardware installation

Visual sensor technology provided by Detectium allows lower CAPEX by being able to cover larger area per sensor installed.

Furthermore, scaling fire safety has never been easier with plug-and-play design, allowing sensors to be integrated with ease.

Data-driven

View past incidents and

simulate fire propagation

Information is critical before and after fire incidents. Avoid potential damages by pinpointing hazard areas by simulation.

Use the gathered data after incidents to perform root-cause analysis and avoid fire incidents in the future.

Customer cases

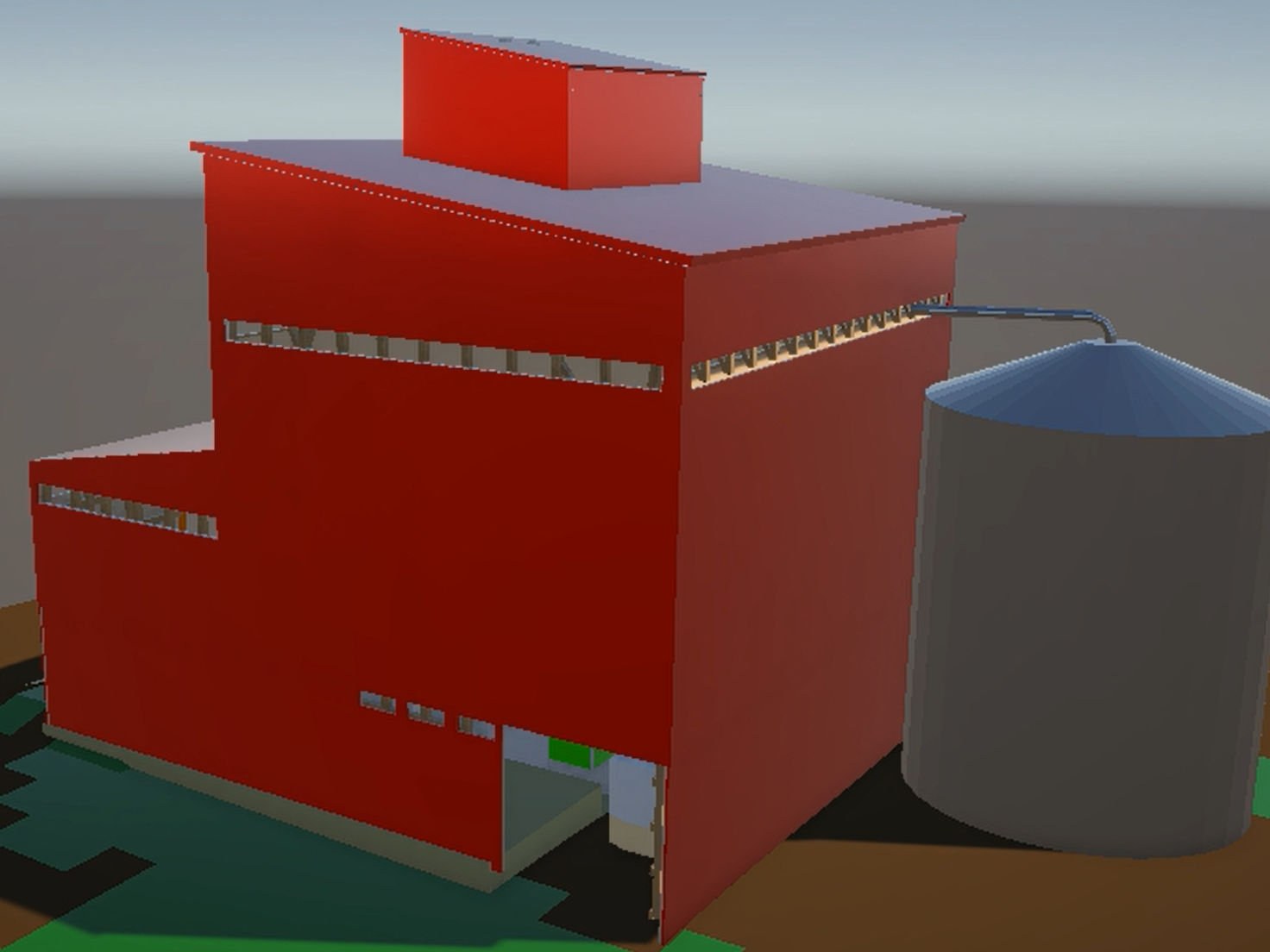

Agriculture & Animal farms

Detectium solution is currently used in animal farms in Finland and Sweden

Industrial sites

Industrial site solution has been deployed the GCC market

Siavash Khajavi, CEO

Siavash is the CEO and co-founder of Detectium holds a PhD and has conducted extensive research on digital twins. His vision is creating a world where the digital representation of all objects can be efficiently and accurately created to enhance the safety in the physical world.

Adriaan Knapen, CINO

Adriaan is a CINO at Detectium. His wide range of expertise includes embedded software development, release and test automation, cloud infrastructure, and software development culture.

Zixuan Liu, CTO

Zixuan is the CTO and a computer vision and embedded system expert at Detectium, enabling seamless integration of image data and AI models. She has deep knowledge of AI research and state-of-the art AI models.

Aarni Huuskonen, CFO

Aarni is the CFO and key account manager at Detectium. Having experience from Nordea and as a business analyst in a scaleup, he ensures Detectium’s path to fast and profitable growth.

Mehdi Moshtaghi, AI developer

Mehdi is an experienced AI developer, responsible for ML Operations, with broad expertise in Computer Vision, Large Language Models, and Diffusion Models, committed to advancing AI innovation.

Yu Dikai, 3D model developer

Yu creates 3D models from environments to enable data fusion in digital twins.

Advisors

Prof.

Kary Främling

He holds a position at Umeå and Aalto University and knowledge in building information management and digital twinning technologies.

Pasi Korhonen

He is the Chief Specialist of business development and innovation with LähiTapiola Insurance Company.

Prof.

Jan Holmström

He is a Professor of operations management with Aalto University, Finland. He is an expert in supply chain management and design science research.

Contact us!

Partners